Slurry and Abrasive

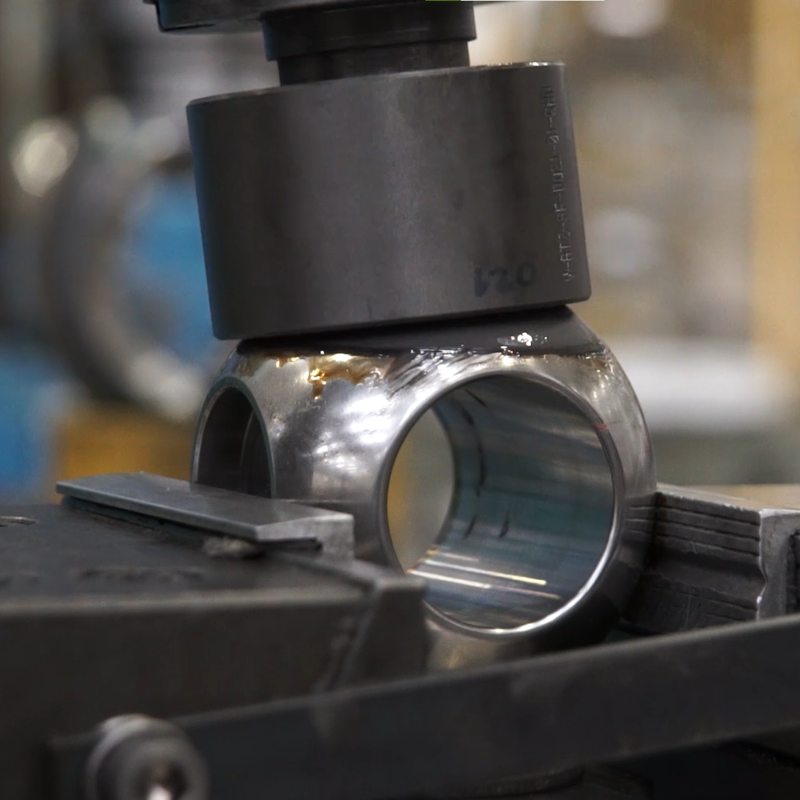

We can provide valves which are able to resist abrasive fluids with a special combination of tungsten or carbide coated metal seats and highly engineered features to protect the sealing areas.

Our valves are also provided with shaped seats that are able to flex and ensure tight shut-off either in high or low pressure conditions. In case of extremely corrosive fluids, we can provide CRA weld overlays on the sealing areas or on all wetted parts. The thickness of external coating can reach up to 1000-1500 microns and guarantee long term protection of the base material from the fluid. The main wetted components (such as body, closures) are coated, whereas the trim is provided in highly corrosion resistance alloys.

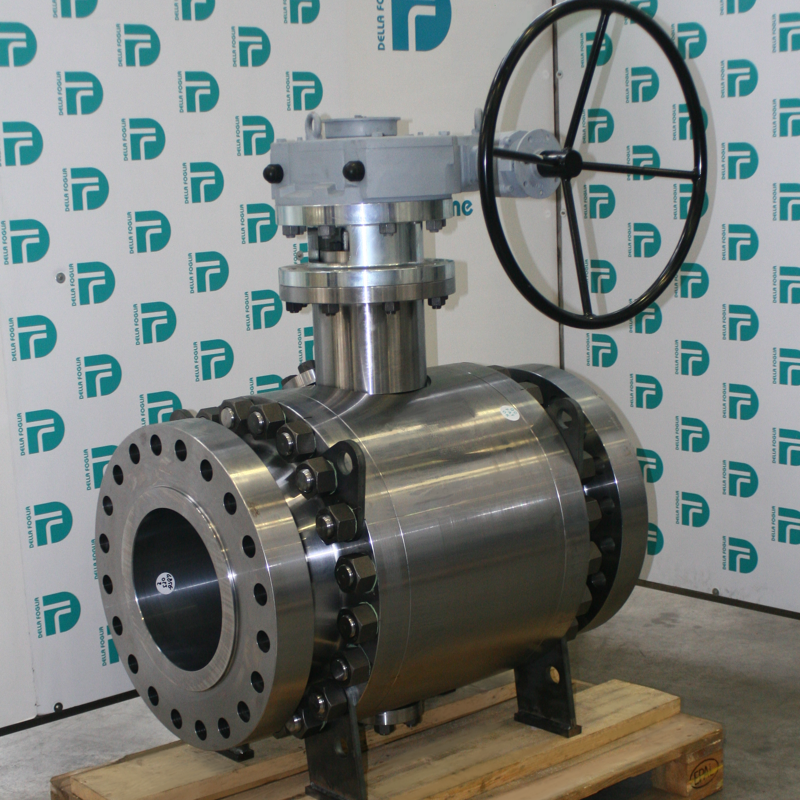

| Service / Application | Slurry and abrasive |

| Valve design | Side or top entry |

| Trim design | Floating or trunnion mounted |

| Size range | From ½” to 64” |

| Pressure range | Class from 150 up to 2.500 |

| Materials grade | CRA weld overlays for aggressive fluids. |

| Materials status | Forging |

| Seals and seats | PFTE, PCTFE, RPTFE, lip seal. Soft or metal seated |

| Extended bonnet | Upon request |

| Design | API 6D, API 6A, API 6A V1 |

| Operator | Lever, gear operated or actuated |