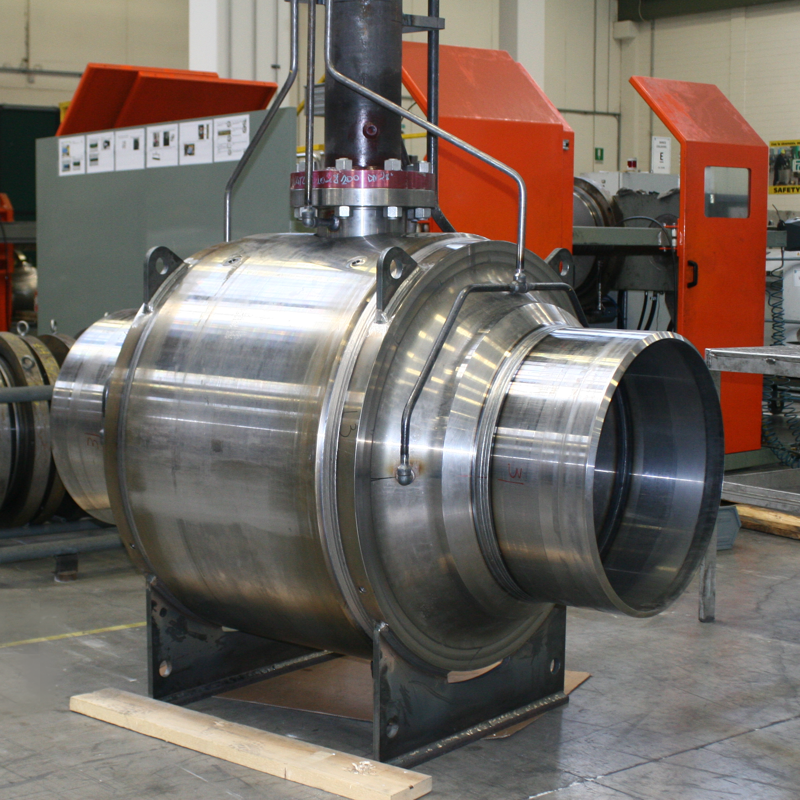

Fully Welded

- Full or reduced bore

- From ½” to 64”

- Class from 150 up to 1.500

In fully welded ball valves body and closures are welded together; the result is a solid assembly with no leakage paths. A fully welded application is a preferable solution when no maintenance is scheduled on valves and when it is mandatory to avoid any external leakage. A typical application is for underground service or subsea. Welding is performed by highly qualified welders, in accordance with all applicable ASME or EN requirements.

| Standard Features | Optional features |

|

|