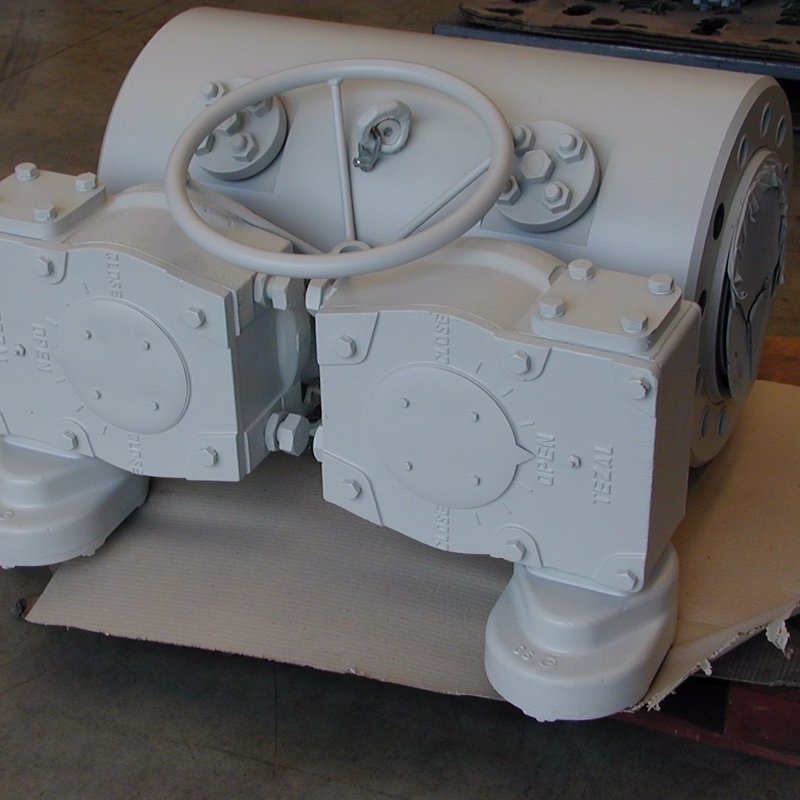

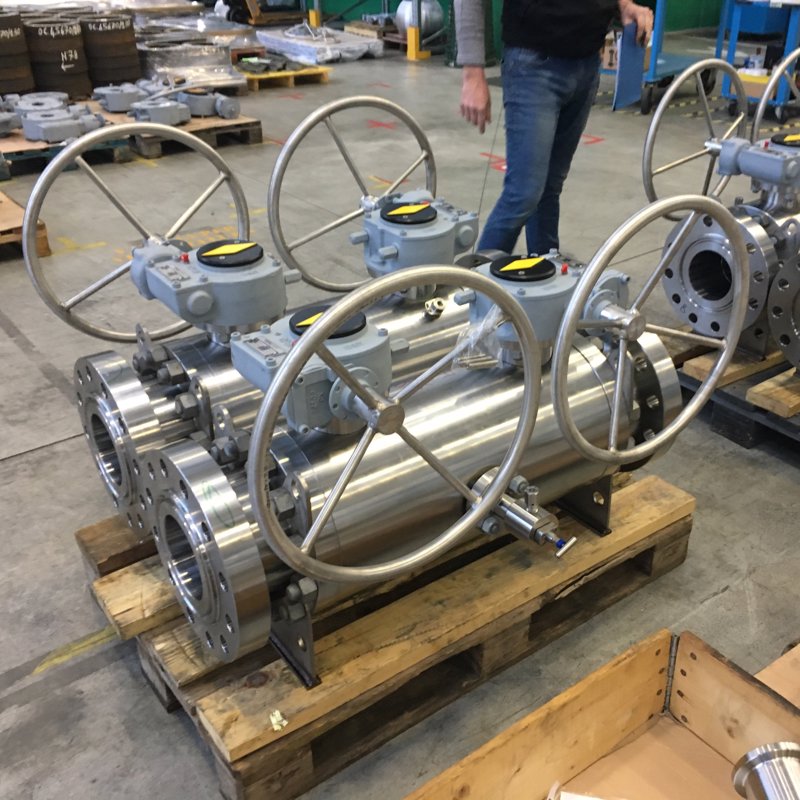

Double Ball

- One, two or three-pieces body design.

- Floating or trunnion design available.

- Bolted or fully welded body.

- Full or reduced bore.

- All forged materials available.

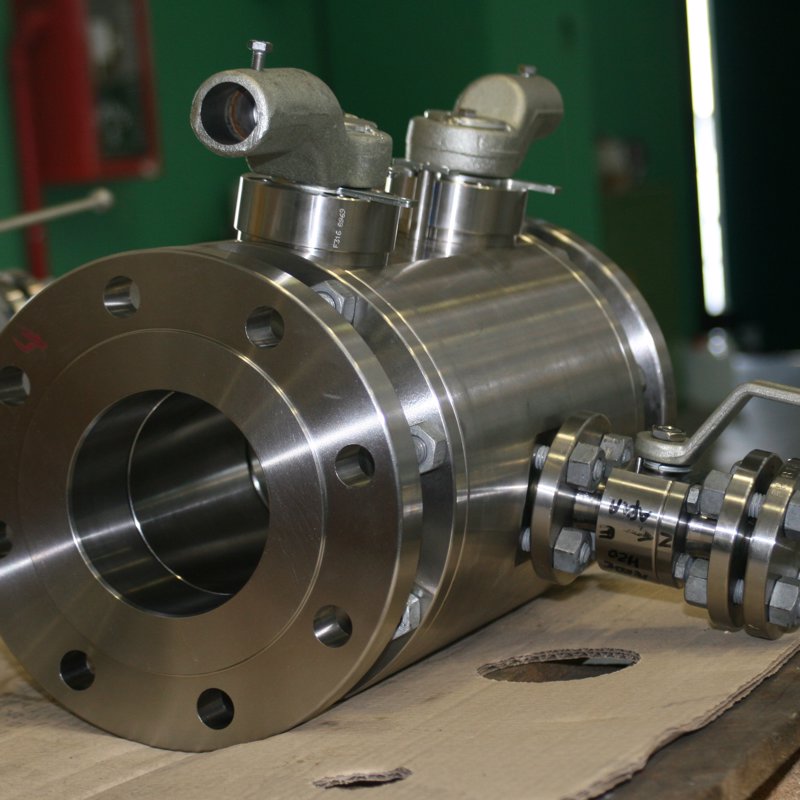

Double Ball Valves are basically made up of two ball valves in one solid body. They provide two physical barriers against downstream leakages with a very compact pattern. A center bleed port between the balls allows testing of valve’s performance and provides a “double block and bleed” feature with maximum safety. The double block and bleed design makes it possible to reduce the pressure to zero in the body cavity, while the line is in pressure and the balls are in closed position. This procedure is possible also while the balls are in opened position if the valve is without equalization hole (Fully Double Block and Bleed). This is suitable to:

- Verify integrity of both seats

- Allow draining and/or flushing of the valve body cavity

- Guarantee prevention of downstream leakage to assure safety of downstream activities

| Application | Reduced space, double block |

| Valve design | Side entry |

| Trim design | Floating or trunnion |

| Sizes | From ½” to 36” (superior sizes can be designed upon request) |

| Pressure range | Class from 150 up to API 6A 15.000 |

|

Materials grade |

Carbon steel, stainless steel, duplex, super duplex, incoloy, exotic material, bronze, titanium. Conforming to the latest MR 01-75 and MR 01-03. CRA weld overlays for aggressive fluids. |

| Materials status | Forged close to final shape |

| Seats | Soft or metal seated |

| Seals | O-rings, lip seals, pressure energized or mechanically loaded stem packings |

| Design | To ASME VIII or ASME B16.34 |

| Operator | Lever, gear operated, actuated |