Cryogenic

- Anti-explosive decompression seals

- Fire safe certified

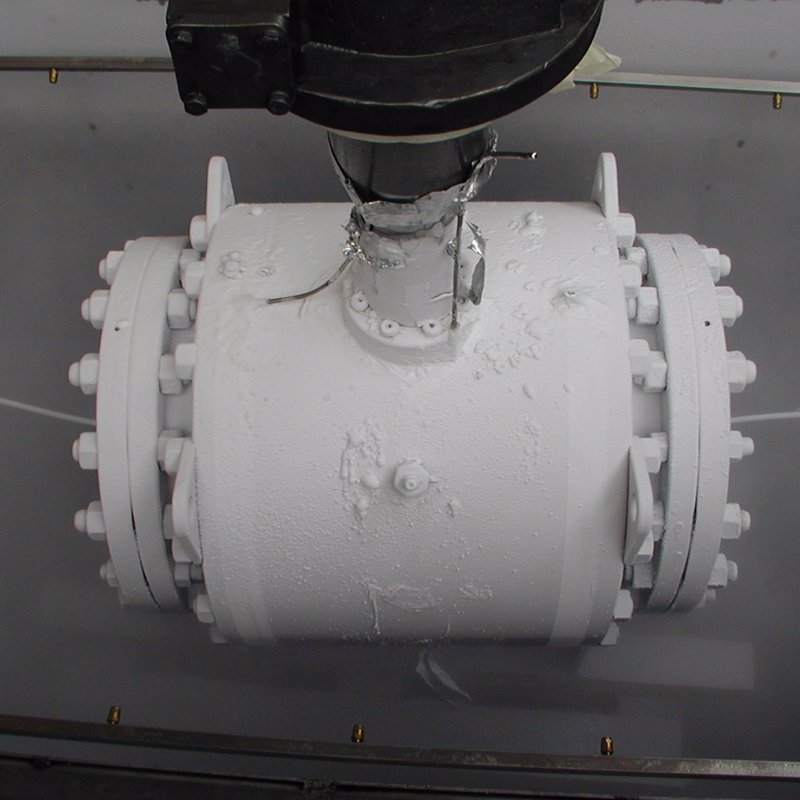

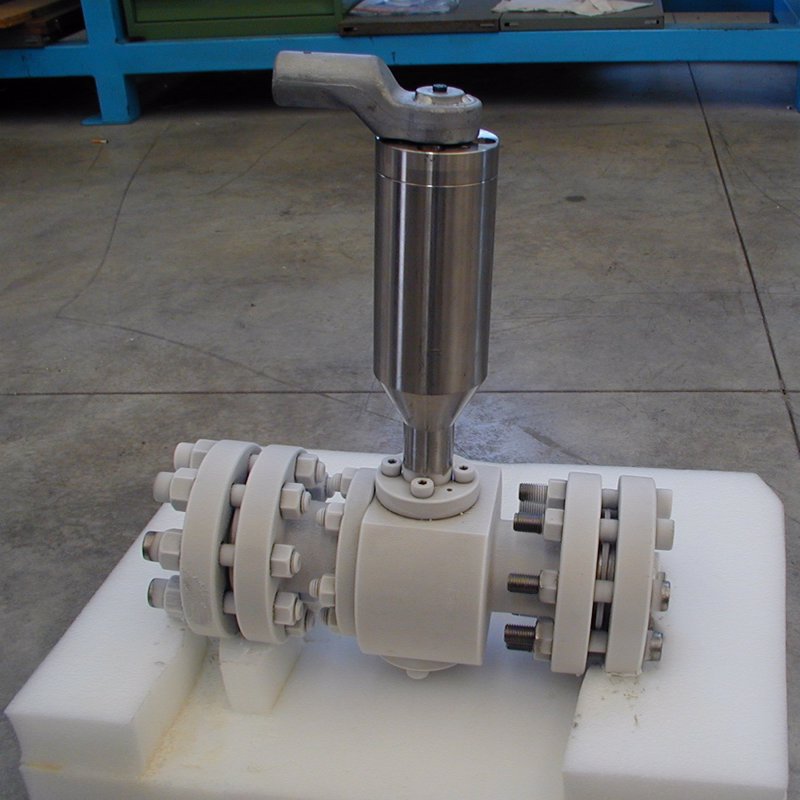

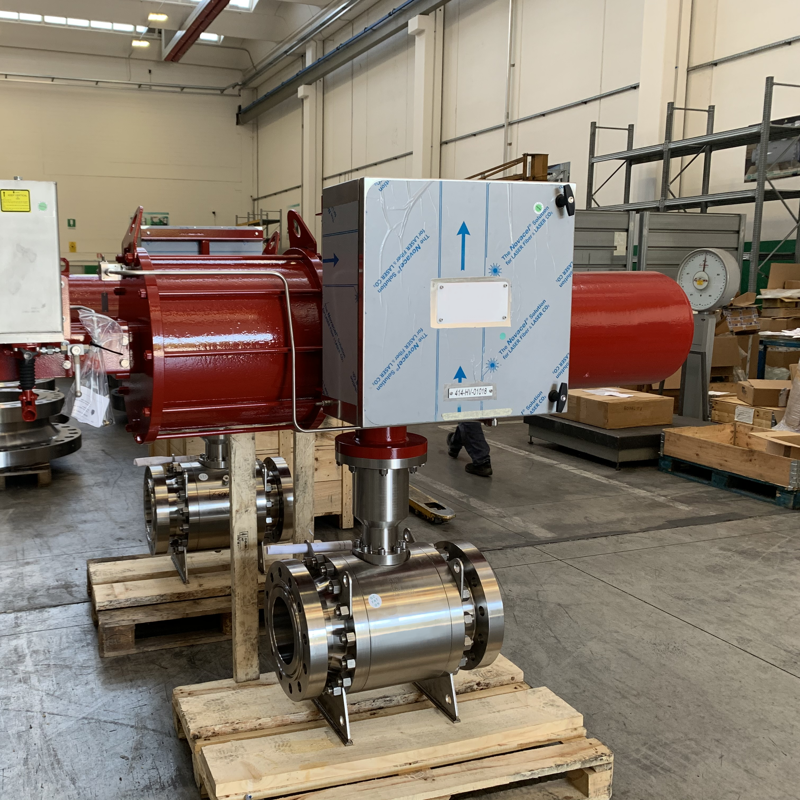

We have developed a long experience in manufacturing valves for low and cryogenic temperatures. A special selection of materials, seals, bonnet design, combined with expertise and careful machining of the sealing surfaces allow our trunnion mounted and floating ball valves to operate down to -196°C. The high quality of our cryogenic valves has been proven by several certifications and prototype testing carried out over the years. Our Assembly and Testing area is provided with all the latest generation technologies to carry out testing at cryogenic temperatures, including leak detection testing and torque testing. Vent and drain can also be provided with pad flanges c/w blind flanges to prevent leakages on threaded connections in sour service.

| Service | Low temperature down to -196°C |

| Valve design | Side entry or top entry |

| Trim design | Floating ball or trunnion mounted |

| Size range | From ½” to 48” |

| Pressure range | Class from 150 up to 2500 |

| Materials grade | Low temperature carbon steel, stainless steel, nitronic 50 |

| Materials status | Forged close to final shape and cast |

| Seals and seats | PFTE, PCTFE, RPTFE, lip seal, PEEK |

| Extended bonnet | Designed to allow vapor space to BS 6364 or Shell MESC SPE 77/200 |

| Design | ASME VIII or ASME B16.34 |

| Operator | Lever, gear operated or actuated |